Temperature Control Unit, 0℃ to 100℃

Industrial heating/cooling units providing cooling and heating from 0°C to 100°C for battery, photovoltaic, energy storage, and semiconductor sectors

-

Model: NEC-2A/W ~ NEC-15A/W

-

Cooling Capacity: 6.0-45kW

-

Temperature precision: ±0.1/±0.2°C

-

High Efficiency & Energy Saving

-

Intelligent Control

-

Multiple Safety Features

-

Durable Construction

-

Easy to Operate

-

Simple Maintenance

-

CE Certification

-

Certified Manufacturing Facility

Specifications

| Model |

|

|

|

|

|

|

|

|

|

|

||

| Cooling capacity | 0℃ liquid temperature | 3.5kW | 5.5kW | 9kW | 10.5kW |

| 20℃ liquid temperature | 6kW | 9kW | 15kW | 18kW | |

| Flow | Flow range | 2-15L/min | 2-20L/min | 3-30L/min | 4-40L/min |

| Flow accuracy | ±0.2L/Min | ±0.2L/Min | ±0.2L/Min | ±0.2L/Min | |

| Outlet circuits | Single/dual/triple optional | ||||

| Temperature | Temperature control range | 0~100℃ | |||

| Temperature control precision | ±0.1/±0.2℃ | ||||

| Temperature sensor | PT100 | ||||

| Pressure | Pressure display/control | Pressure display and adjustable pressure control | |||

| Pressure range | 2-3bar | ||||

| Communication interface | Modbus RTU protocol, RS485 port, optional CAN bus, or Ethernet (TCP/IP) | ||||

| Power supply | 380V/3Ph/50Hz (non-standard power supply customizable) | ||||

| Compressor type | Imported flexible scroll compressor | ||||

| Water pump type | Stainless steel multistage variable-frequency water pump | ||||

| Evaporator type | Stainless steel coil type/stainless steel shell-and-tube type | ||||

| Condenser type (air-cooled) | Hydrophilic aluminum fins + internal thread copper tubes | ||||

| Condenser type (water-cooled) | Shell-and-tube type | ||||

| Expansion device | Expansion valve | ||||

| Control panel | 7-inch touch screen | ||||

| Safety protection | Pressure, current, temperature, flow, liquid level, and power protection | ||||

| Pipe connection size | G-3/4” | ||||

| Refrigerant type | R410A/R407C | ||||

| Model |

|

|

|

|

|

|

|

|

|

|

||

| Cooling capacity | 0℃ liquid temperature | 14.5kW | 14.5kW | 22kW | 27kW |

| 20℃ liquid temperature | 24kW | 30kW | 36kW | 45kW | |

| Flow | Flow range | 4-40L/min | 4-40L/min | 5-50L/min | 5-50L/min |

| Flow accuracy | ±0.2L/Min | ±0.2L/Min | ±0.2L/Min | ±0.2L/Min | |

| Outlet circuits | Single/dual/triple optional | ||||

| Temperature | Temperature control range | 0~100℃ | |||

| Temperature control precision | ±0.1/±0.2℃ | ||||

| Temperature sensor | PT100 | ||||

| Pressure | Pressure display/control | Pressure display and adjustable pressure control | |||

| Pressure range | 2-3bar | ||||

| Communication interface | Modbus RTU protocol, RS485 port, optional CAN bus, or Ethernet (TCP/IP) | ||||

| Power supply | 380V/3Ph/50Hz (non-standard power supply customizable) | ||||

| Compressor type | Imported flexible scroll compressor | ||||

| Water pump type | Stainless steel multistage variable-frequency water pump | ||||

| Evaporator type | Stainless steel coil type/stainless steel shell-and-tube type | ||||

| Condenser type (air-cooled) | Hydrophilic aluminum fins + internal thread copper tubes | ||||

| Condenser type (water-cooled) | Shell-and-tube type | ||||

| Expansion device | Expansion valve | ||||

| Control panel | 7-inch touch screen | ||||

| Safety protection | Pressure, current, temperature, flow, liquid level, and power protection | ||||

| Pipe connection size | G-3/4” | ||||

| Refrigerant type | R410A/R407C | ||||

Customized specifications are available upon request. Please

- Energy Efficiency

- Innovation

- Safety Features

- Precision Manufacturing

- Various Applications

Energy Performance

-

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes -

20% Improve heat transfer efficiency by aboutWave-Shaped Fins

20% Improve heat transfer efficiency by aboutWave-Shaped Fins -

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve -

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System -

10% Enhances air circulation by aboutOptimized Airflow Path Design

10% Enhances air circulation by aboutOptimized Airflow Path Design -

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

Innovation

-

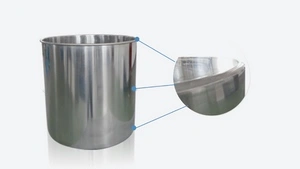

Stainless Steel Evaporator

Stainless Steel Evaporator -

V-Shaped Condenser

V-Shaped Condenser -

Cylindrical Water Tank

Cylindrical Water Tank -

Low-Noise Fan

Low-Noise Fan -

Touch-Screen Controller

Touch-Screen Controller -

Advanced Control System

Advanced Control System

Multiple Safety Features

-

Over-Temperature Protection

Over-Temperature Protection -

Current Protection

Current Protection -

Self-Diagnosis

Self-Diagnosis -

Intelligent Antifreeze

Intelligent Antifreeze -

Water Flow Alarm

Water Flow Alarm -

Water Level Alarm

Water Level Alarm -

Pressure Alarm

Pressure Alarm -

Timer On/Off

Timer On/Off

Precision Manufacturing

-

Precision Sheet Metal Forming

Precision Sheet Metal Forming -

Stamped Flow Guide Rings

Stamped Flow Guide Rings -

Robotic Bending System (Bystronic, Switzerland)

Robotic Bending System (Bystronic, Switzerland) -

Laser Welding Technology

Laser Welding Technology -

Automated Insulation Material Cutting

Automated Insulation Material Cutting -

Automated Joint Welding

Automated Joint Welding

Customer Application Site

With over 20 years of experience in the industrial cooling industry, KANSA designs and manufactures a variety of industrial chillers and process temperature control equipment in-house to ensure consistent quality, reliable operation and exceptional temperature stability of ±0.05°C. The company holds CE, ISO9001-2016, ISO45001 and other international certifications, serving more than 70,000 customers worldwide.