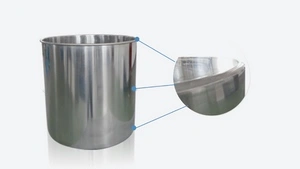

Shell-and-Tube Evaporator

The shell-and-tube evaporator is made of durable stainless steel, providing corrosion resistance and mechanical strength. It is specifically designed for clean or corrosive media. Featuring a compact structure, high heat transfer efficiency, and strong pressure-bearing capacity, it is widely used in industries with strict hygiene requirements, such as pharmaceuticals, food, and chemicals. As a key high-efficiency heat exchange component in chillers, heat pumps, and process cooling systems, it ensures long-term stable operation of the equipment.

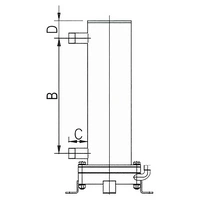

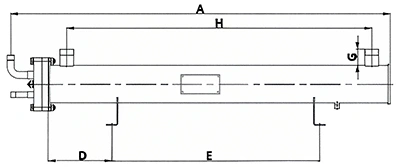

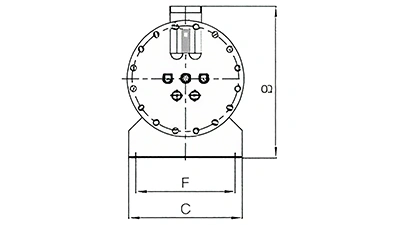

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||

| A | B | C | D | E | F | |||

|

|

1HP | DN15 | 550 | 370 | 40 | 50 | 193 | 193 |

|

|

2HP | DN20 | 550 | 370 | 40 | 50 | 212 | 212 |

|

|

3HP | DN25 | 550 | 370 | 40 | 50 | 235 | 235 |

|

|

4HP | DN25 | 550 | 370 | 40 | 50 | 255 | 255 |

|

|

5HP | DN25 | 600 | 420 | 40 | 50 | 285 | 285 |

|

|

6HP | DN25 | 600 | 420 | 40 | 50 | 285 | 285 |

|

|

7HP | DN25 | 600 | 420 | 40 | 50 | 305 | 305 |

|

|

8HP | DN25 | 650 | 475 | 40 | 60 | 305 | 305 |

|

|

10HP | DN40 | 650 | 455 | 50 | 70 | 330 | 330 |

|

|

12HP | DN40 | 650 | 455 | 50 | 70 | 330 | 330 |

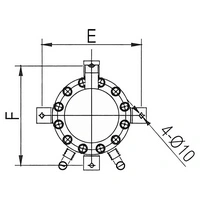

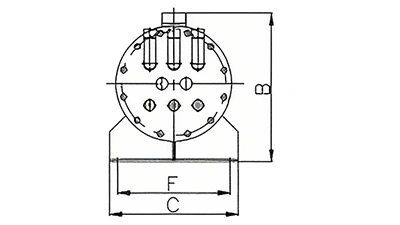

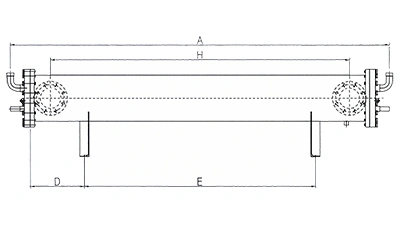

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

3HP | DN25 | 585 | 260 | 200 | 100 | 200 | 160 | 40 | 370 |

|

|

4HP | DN25 | 585 | 260 | 200 | 100 | 200 | 160 | 40 | 370 |

|

|

5HP | DN25 | 618 | 277 | 200 | 100 | 300 | 180 | 40 | 404 |

|

|

6HP | DN25 | 618 | 277 | 200 | 100 | 300 | 180 | 40 | 404 |

|

|

7HP | DN25 | 618 | 290 | 200 | 100 | 300 | 180 | 40 | 404 |

|

|

8HP | DN25 | 708 | 290 | 200 | 100 | 350 | 180 | 50 | 475 |

|

|

10HP | DN40 | 828 | 290 | 200 | 100 | 450 | 180 | 50 | 560 |

|

|

12HP | DN40 | 828 | 290 | 200 | 100 | 450 | 180 | 50 | 560 |

|

|

15HP | DN40 | 1118 | 290 | 200 | 175 | 600 | 180 | 50 | 860 |

|

|

20HP | DN50 | 1603 | 277 | 200 | 275 | 900 | 180 | 65 | 1320 |

|

|

25HP | DN50 | 1603 | 290 | 200 | 275 | 900 | 180 | 65 | 1320 |

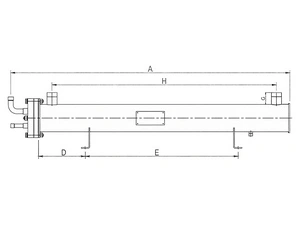

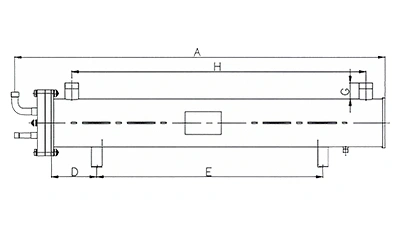

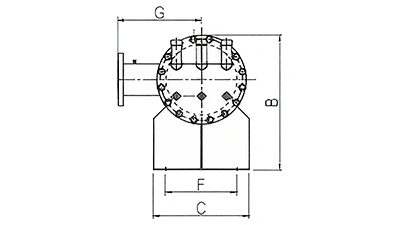

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

4HP*2 | DN25 | 708 | 290 | 200 | 100 | 350 | 160 | 50 | 475 |

|

|

5HP*2 | DN25 | 828 | 290 | 200 | 100 | 450 | 190 | 50 | 560 |

|

|

6HP*2 | DN25 | 828 | 290 | 200 | 100 | 450 | 160 | 50 | 560 |

|

|

7,5HP*2 | DN25 | 1118 | 290 | 200 | 175 | 600 | 190 | 50 | 860 |

|

|

10HP*2 | DN40 | 1603 | 277 | 200 | 275 | 900 | 180 | 65 | 1320 |

|

|

12HP*2 | DN40 | 1603 | 290 | 200 | 275 | 900 | 180 | 65 | 1320 |

|

|

15HP*2 | DN40 | 1603 | 290 | 200 | 275 | 900 | 180 | 65 | 1320 |

|

|

20HP*2 | DN50 | 1615 | 365 | 280 | 275 | 900 | 200 | 65 | 1320 |

|

|

25HP*2 | DN65 | 1615 | 436 | 320 | 275 | 900 | 280 | 65 | 1320 |

|

|

30HP*2 | DN65 | 1650 | 477 | 320 | 275 | 935 | 280 | 100 | 1335 |

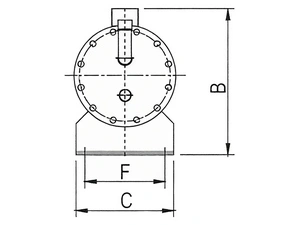

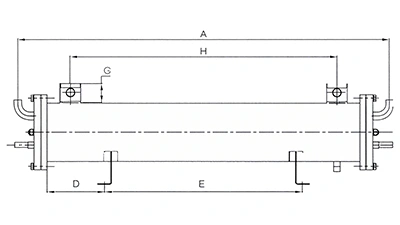

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

5HP*3 | DN40 | 1118 | 290 | 200 | 175 | 175 | 180 | 50 | 860 |

|

|

10HP*3 | DN50 | 1615 | 365 | 250 | 275 | 275 | 200 | 65 | 1320 |

|

|

12HP*3 | DN50 | 1615 | 365 | 250 | 275 | 275 | 200 | 65 | 1320 |

|

|

20HP*3 | DN65 | 1650 | 477 | 320 | 275 | 275 | 280 | 100 | 1335 |

|

|

25HP*3 | DN65 | 2315 | 477 | 320 | 275 | 275 | 280 | 100 | 1865 |

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

10HP*4 | DN50 | 1612 | 453 | 320 | 250 | 859 | 280 | 100 | 1160 |

|

|

12HP*4 | DN65 | 1612 | 468 | 320 | 250 | 859 | 280 | 100 | 1160 |

|

|

15HP*4 | DN65 | 1612 | 468 | 320 | 250 | 859 | 280 | 100 | 1160 |

|

|

20HP*4 | DN80 | 2326 | 468 | 320 | 250 | 1550 | 280 | 100 | 1870 |

|

|

25HP*4 | DN80 | 2578 | 468 | 320 | 250 | 1802 | 280 | 100 | 2122 |

|

|

30HP*4 | DN80 | 2578 | 508 | 320 | 250 | 1802 | 280 | 100 | 2122 |

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

12HP*5 | DN65 | 1612 | 482 | 320 | 250 | 859 | 280 | 100 | 1160 |

|

|

25HP*5 | DN100 | 2578 | 588 | 400 | 350 | 1802 | 350 | 350 | 2122 |

|

|

25HP*6 | DN100 | 3128 | 588 | 400 | 350 | 1802 | 350 | 350 | 2672 |

- Energy Efficiency

- Innovation

- Safety Features

- Precision Manufacturing

-

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes -

20% Improve heat transfer efficiency by aboutWave-Shaped Fins

20% Improve heat transfer efficiency by aboutWave-Shaped Fins -

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve -

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System -

10% Enhances air circulation by aboutOptimized Airflow Path Design

10% Enhances air circulation by aboutOptimized Airflow Path Design -

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

-

Stainless Steel Evaporator

Stainless Steel Evaporator -

V-Shaped Condenser

V-Shaped Condenser -

Cylindrical Water Tank

Cylindrical Water Tank -

Low-Noise Fan

Low-Noise Fan -

Touch-Screen Controller

Touch-Screen Controller -

Advanced Control System

Advanced Control System

-

Over-Temperature Protection

Over-Temperature Protection -

Current Protection

Current Protection -

Self-Diagnosis

Self-Diagnosis -

Intelligent Antifreeze

Intelligent Antifreeze -

Water Flow Alarm

Water Flow Alarm -

Water Level Alarm

Water Level Alarm -

Pressure Alarm

Pressure Alarm -

Timer On/Off

Timer On/Off

-

Precision Sheet Metal Forming

Precision Sheet Metal Forming -

Stamped Flow Guide Rings

Stamped Flow Guide Rings -

Robotic Bending System (Bystronic, Switzerland)

Robotic Bending System (Bystronic, Switzerland) -

Laser Welding Technology

Laser Welding Technology -

Automated Insulation Material Cutting

Automated Insulation Material Cutting -

Automated Joint Welding

Automated Joint Welding

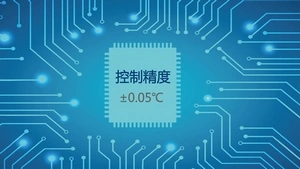

With over 20 years of experience in the industrial cooling industry, KANSA designs and manufactures a variety of industrial chillers and process temperature control equipment in-house to ensure consistent quality, reliable operation and exceptional temperature stability of ±0.05°C. The company holds CE, ISO9001-2016, ISO45001 and other international certifications, serving more than 70,000 customers worldwide.