Founded in 2006 and headquartered in Shanghai’s Pudong New Area, KANSA specializes in the research, development, and manufacturing of a full range of industrial cooling equipment.

Driven by continuous innovation and a forward-looking understanding of customer needs and industry trends, KANSA has become a trusted manufacturer of industrial chillers, scroll chillers, cabinet air conditioners, oil coolers, and coolant chillers. Since 2016, KANSA has been recognized three consecutive times as a Shanghai High-Tech Enterprise.

A strong R&D capability is the foundation of KANSA’s sustainable growth.

Equipped with internationally advanced intelligent manufacturing facilities, precision testing instruments, and a skilled engineering team, KANSA ensures that every product embodies cutting-edge technology and uncompromising quality.

Our continued pursuit of innovation allows us to meet diverse application demands while upholding KANSA’s core values of integrity, precision, and excellence.

Across China, KANSA is trusted by thousands of customers for its breakthrough technologies, professional engineering solutions, and comprehensive technical support.

Our chillers, cabinet air conditioners and temperature control units are widely applied in machinery, electronics, printing, new energy, plastics, textiles, food processing, pharmaceuticals, chemicals, and renewable energy, serving as integral components in countless industrial setups.

KANSA has earned broad recognition from equipment manufacturers, engineers, and end users alike.

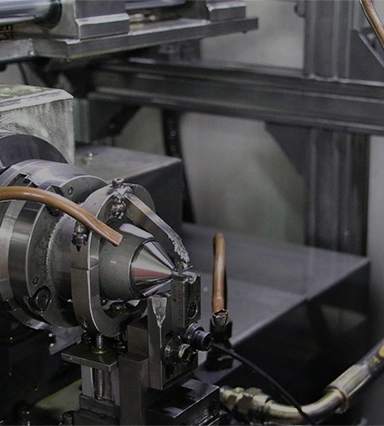

Industrial Chiller Manufacturing Workshop

Industrial Chiller Manufacturing Workshop

Shanghai KANSA is located in Pudong New Area and operates a 20,000 m² modern production plant with complete supporting facilities.

The site employs a large team of experienced managers, technicians, and skilled workers, supported by advanced production and inspection systems, including:

- Fully automated sheet metal flexible production lines

- AMADA digital press brakes

- Automatic laser cutting and material handling systems

- Complete fin heat exchanger production line

- High-vacuum degreasing furnace

- Automatic water tank and fully automatic refrigerant piping production lines

- Certified product testing and electrical safety platforms

Following KANSA’s strict quality management system, we ensure that every unit meets the highest standards of reliability and performance.

Amada CNC Turret Punch Press

Amada CNC Turret Punch Press CNC Bending Machine

CNC Bending Machine Sheet Metal Flexibile Production Line

Sheet Metal Flexibile Production Line Automatic Laser Cutting Machine

Automatic Laser Cutting Machine Fin Press

Fin Press Automatic U-Bending Machine for Heat Exchangers

Automatic U-Bending Machine for Heat Exchangers Machining Center

Machining Center CNC Lathe

CNC Lathe Product Test Center 1

Product Test Center 1 Product Test Center 2

Product Test Center 2 Bystronic robotic press brake bending cell 1

Bystronic robotic press brake bending cell 1 Bystronic robotic press brake bending cell 2

Bystronic robotic press brake bending cell 2

KANSA’s Shenzhen plant, located in Bao’an District, covers 4,800 m² and maintains synchronized technical and production management standards with the Shanghai headquarters.

Equipped with AMADA digital press brakes, high-speed laser cutting machines, and complete fin production and refrigerant piping production lines, the Shenzhen facility focuses on the production of air-cooled, water-cooled, and screw chillers, serving as one of South China’s most advanced and intelligent industrial chiller manufacturing bases.

Reception Area

Reception Area Meeting Room

Meeting Room CNC Turret Punch Press

CNC Turret Punch Press High Power Laser Cutting Machine

High Power Laser Cutting Machine Amada CNC Press Brake

Amada CNC Press Brake CNC 3D Tube Bender

CNC 3D Tube Bender Automatic Copper Tube Flaring Machine

Automatic Copper Tube Flaring Machine Automatic Welding Machine

Automatic Welding Machine Tube Bending Machine

Tube Bending Machine

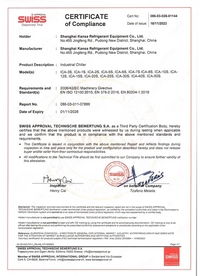

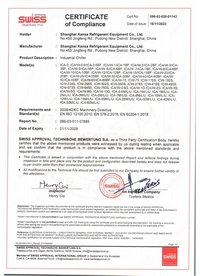

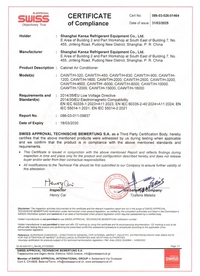

CE Certifications

CE Certifications CE Certifications

CE Certifications CE Certifications

CE Certifications CE Certifications

CE Certifications Quality Management System Certification

Quality Management System Certification Intellectual Property Compliance Certification

Intellectual Property Compliance Certification Environmental Management System Certification

Environmental Management System Certification Occupational Health and Safety Management System Certification

Occupational Health and Safety Management System Certification Integration of Informatization and Industrialization Management Certification

Integration of Informatization and Industrialization Management Certification Digital Transformation Management System Certification

Digital Transformation Management System Certification

Your Trusted Technical Partner for Comprehensive Service and Reliable Support

-

Rapid Response

Rapid Response24/7 technical hotline with prompt remote guidance based on issue priority.

-

Remote Technical Support

Remote Technical SupportAssistance via email or video for operation guidance, fault diagnosis, and parameter adjustments.

-

Spare Parts Supply

Spare Parts SupplyQuick delivery of replacement parts to minimize downtime.

KANSA is committed to providing end-to-end support throughout the entire product lifecycle, ensuring stable, efficient, and reliable operation of your equipment at all times.