KANSA industrial chillers redefine industrial cooling standards through advanced engineering and manufacturing precision. Core competitiveness is reflected in the optimized design and construction of key components.

-

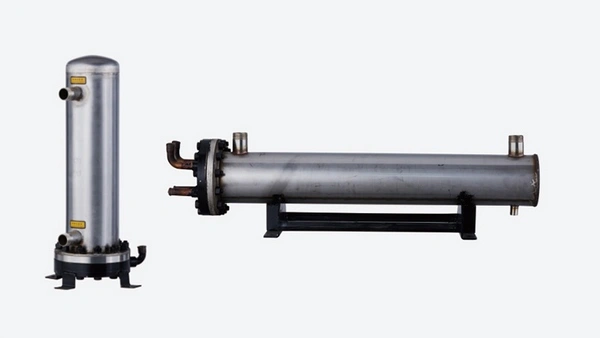

The stainless-steel shell-and-tube evaporator serves as the central element of efficient refrigeration performance. Constructed from food-grade 304/316 stainless steel, the evaporator provides exceptional corrosion resistance and hygiene, meeting the stringent material requirements of chemical and food processing industries. The shell-and-tube configuration offers an expanded heat exchange surface, ensuring full refrigerant–water contact, high thermal efficiency, strong pressure resistance, and stable operation under demanding conditions.

-

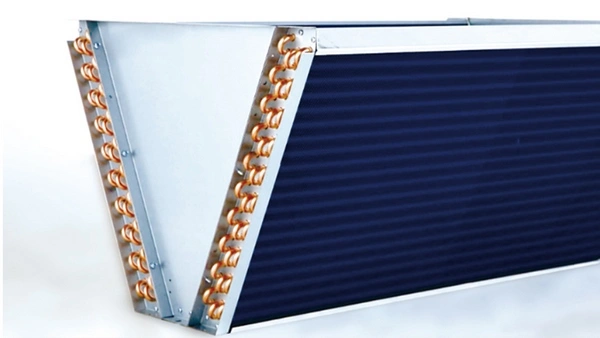

The V-type fin condenser guarantees high-efficiency heat dissipation. The compact V-shaped configuration reduces installation footprint and forms an optimized airflow field. Precision-inserted copper tubes combined with hydrophilic aluminum fins significantly improve heat transfer performance. The condenser’s enhanced resistance to fouling and ease of cleaning ensure reliable operation and sustained cooling capacity even in high-temperature environments.

-

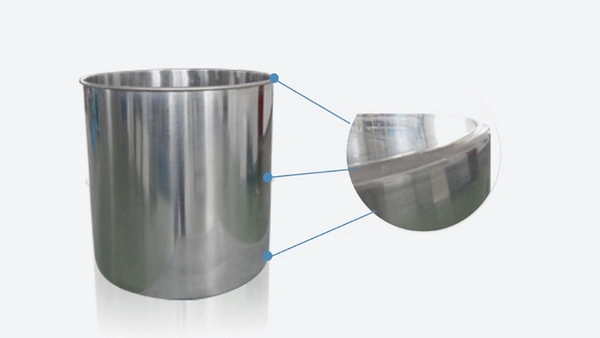

The cylindrical water tank design combines structural integrity with functional efficiency. The smooth inner surface prevents sediment accumulation and facilitating maintenance. The evenly distributed internal pressure and smooth flow path minimize energy loss and enhance circulation stability.

-

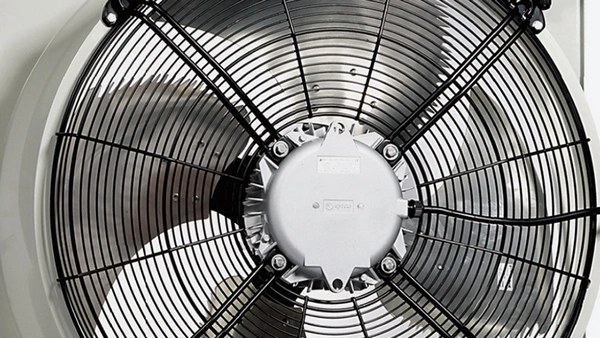

The low-noise axial fan ensures an optimized acoustic and aerodynamic balance. Large-diameter, low-speed blades combined with an acoustically engineered shroud provide sufficient airflow with minimal noise emission, maintaining efficient operation in noise-sensitive industrial environments.

-

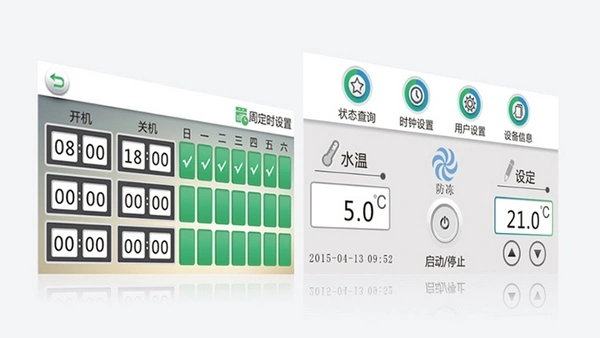

The intelligent touch-screen control system functions as the operational core of the unit. The full-color interface enables direct access to temperature settings, parameter adjustments, status monitoring, and diagnostic functions. The control logic automatically adapts system operation according to load variations, ensuring precise temperature regulation, high energy efficiency, and simplified process control.

-

Over-temperature protection

Over-temperature protection -

Over-current protection

Over-current protection -

Self-diagnostic system

Self-diagnostic system -

Intelligent anti-freeze protection

Intelligent anti-freeze protection -

Water flow alarm

Water flow alarm -

Water level alarm

Water level alarm -

Pressure alarm

Pressure alarm -

Programmable start/stop timer

Programmable start/stop timer