Shell-and-Tube Condenser

The shell-and-tube condenser uses reliable heat exchange tubes and an optimized structural design, providing heat transfer efficiency and strong pressure resistance. Its compact structure, stable operation, and corrosion resistance make it suitable for medium- and large-scale refrigeration systems. Widely used in central air conditioning, cold storage, and industrial cooling applications, it ensures long-term, efficient system performance.

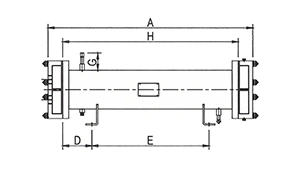

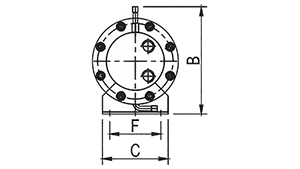

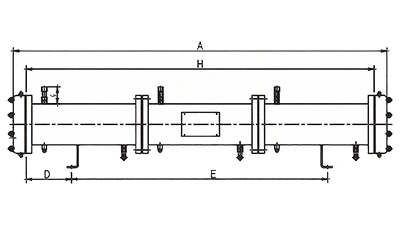

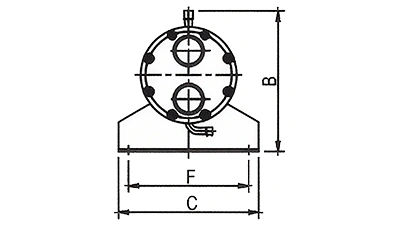

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

5HP | DN25 | 680 | 295 | 180 | 100 | 360 | 140 | 70 | 560 |

|

|

6HP | DN25 | 680 | 295 | 180 | 100 | 360 | 140 | 70 | 560 |

|

|

7HP | DN25 | 840 | 295 | 180 | 120 | 480 | 140 | 70 | 720 |

|

|

8HP | DN40 | 840 | 295 | 180 | 120 | 480 | 140 | 70 | 720 |

|

|

10HP | DN40 | 900 | 310 | 200 | 140 | 500 | 160 | 70 | 780 |

|

|

12HP | DN40 | 900 | 310 | 200 | 140 | 500 | 160 | 70 | 780 |

|

|

15HP | DN40 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1865 |

|

|

20HP | DN50 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1365 |

|

|

25HP | DN50 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1865 |

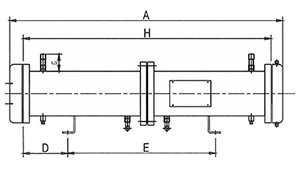

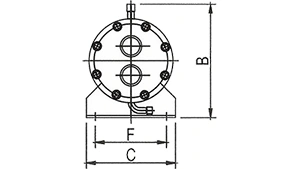

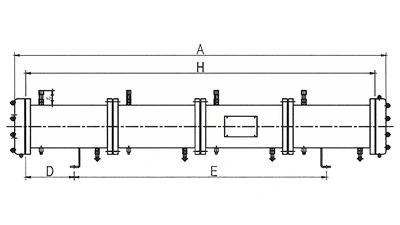

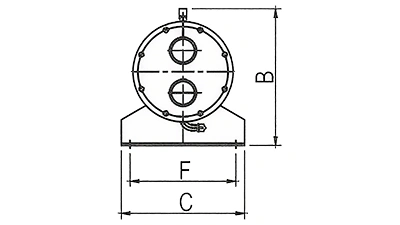

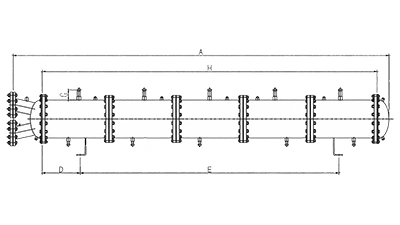

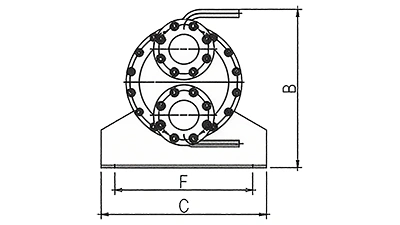

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

4HP*2 | DN40 | 1107 | 320 | 250 | 180 | 600 | 200 | 70 | 1005 |

|

|

5HP*2 | DN40 | 1107 | 320 | 250 | 180 | 600 | 200 | 70 | 1005 |

|

|

6HP*2 | DN40 | 1107 | 320 | 250 | 180 | 600 | 200 | 70 | 1005 |

|

|

7.5HP*2 | DN40 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1365 |

|

|

10HP*2 | DN50 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1365 |

|

|

12HP*2 | DN50 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1365 |

|

|

15HP*2 | DN50 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1365 |

|

|

20HP*2 | DN50 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1365 |

|

|

25HP*2 | DN65 | 1480 | 320 | 250 | 180 | 1000 | 200 | 70 | 1365 |

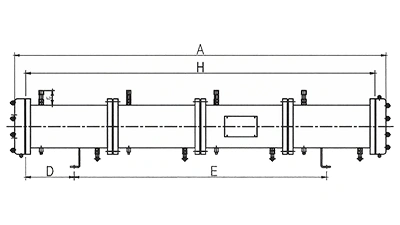

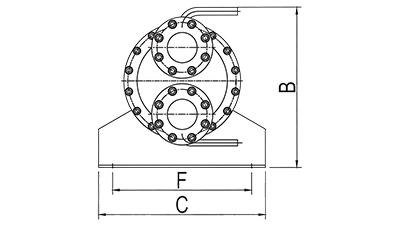

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

5HP*3 | DN50 | 1648 | 350 | 350 | 200 | 1130 | 300 | 70 | 1534 |

|

|

10HP*3 | DN50 | 2014 | 350 | 350 | 303 | 1300 | 300 | 70 | 1900 |

|

|

12HP*3 | DN65 | 2014 | 350 | 350 | 303 | 1300 | 300 | 70 | 1890 |

|

|

20HP*3 | DN80 | 2014 | 410 | 350 | 303 | 1300 | 300 | 70 | 1900 |

|

|

25HP*3 | DN80 | 2014 | 410 | 350 | 303 | 1300 | 300 | 70 | 1890 |

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

10HP*4 | DN65 | 1913 | 388 | 350 | 250 | 1300 | 300 | 70 | 1800 |

|

|

12HP*4 | DN65 | 1913 | 388 | 350 | 250 | 1300 | 300 | 70 | 1800 |

|

|

15HP*4 | DN65 | 1913 | 388 | 350 | 250 | 1300 | 300 | 70 | 1800 |

|

|

20HP*4 | DN80 | 1913 | 388 | 350 | 250 | 1300 | 300 | 70 | 1800 |

|

|

25HP*4 | DN80 | 2650 | 410 | 350 | 303 | 1800 | 300 | 70 | 2540 |

| Heat exchanger model | Compressor horsepower | Water pipe connection | Dimensions (mm) | |||||||

| A | B | C | D | E | F | G | H | |||

|

|

12HP*5 | DN65 | 2364 | 388 | 350 | 260 | 1750 | 300 | 70 | 2250 |

|

|

25HP*5 | DN100 | 3220 | 575 | 600 | 325 | 2220 | 500 | 90 | 2870 |

- Energy Efficiency

- Innovation

- Safety Features

- Precision Manufacturing

-

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes -

20% Improve heat transfer efficiency by aboutWave-Shaped Fins

20% Improve heat transfer efficiency by aboutWave-Shaped Fins -

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve -

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System -

10% Enhances air circulation by aboutOptimized Airflow Path Design

10% Enhances air circulation by aboutOptimized Airflow Path Design -

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

-

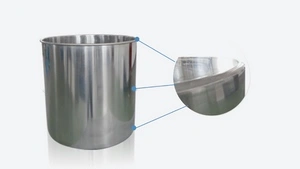

Stainless Steel Evaporator

Stainless Steel Evaporator -

V-Shaped Condenser

V-Shaped Condenser -

Cylindrical Water Tank

Cylindrical Water Tank -

Low-Noise Fan

Low-Noise Fan -

Touch-Screen Controller

Touch-Screen Controller -

Advanced Control System

Advanced Control System

-

Over-Temperature Protection

Over-Temperature Protection -

Current Protection

Current Protection -

Self-Diagnosis

Self-Diagnosis -

Intelligent Antifreeze

Intelligent Antifreeze -

Water Flow Alarm

Water Flow Alarm -

Water Level Alarm

Water Level Alarm -

Pressure Alarm

Pressure Alarm -

Timer On/Off

Timer On/Off

-

Precision Sheet Metal Forming

Precision Sheet Metal Forming -

Stamped Flow Guide Rings

Stamped Flow Guide Rings -

Robotic Bending System (Bystronic, Switzerland)

Robotic Bending System (Bystronic, Switzerland) -

Laser Welding Technology

Laser Welding Technology -

Automated Insulation Material Cutting

Automated Insulation Material Cutting -

Automated Joint Welding

Automated Joint Welding

With over 20 years of experience in the industrial cooling industry, KANSA designs and manufactures a variety of industrial chillers and process temperature control equipment in-house to ensure consistent quality, reliable operation and exceptional temperature stability of ±0.05°C. The company holds CE, ISO9001-2016, ISO45001 and other international certifications, serving more than 70,000 customers worldwide.