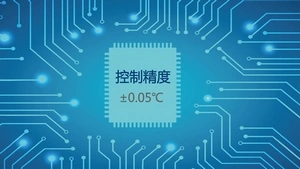

2.7-29.5kW Air-Cooled Industrial Chiller (High Temperature Control Precision of ±0.05 ℃)

-

Model: ICA-1G~ICA-10G

-

Cooling Capacity: 2.7-29.5kW

-

Temperature precision: ±0.05°C

-

High Efficiency & Energy Saving

-

Intelligent Control

-

Multiple Safety Features

-

Durable Construction

-

Easy to Operate

-

Simple Maintenance

-

CE Certification

-

Certified Manufacturing Facility

The high-precision air-cooled industrial chiller is specifically designed for applications requiring exceptionally accurate temperature control. Equipped with imported compressors and intelligent PID temperature regulation technology, it achieves temperature stability within ±0.05 °C or higher, ensuring absolute reliability of production processes.

This chiller is widely used in precision laser processing, semiconductor testing, medical equipment, and laboratory environments, providing essential support for the efficient operation and reliable quality of advanced equipment.

| Model |

|

|

|

|

|

|

||

| Cooling capacity | kW | 2.7 | 5.0 | 9.1 | 15.0 | 23.0 | 29.5 | |

| 10³ kcal/h | 2.3 | 4.5 | 7.8 | 12.9 | 19.8 | 25.4 | ||

| Power supply | V/Ph/Hz | 220V/1/50Hz | 380V/3/50Hz | |||||

| Total power input | kW | 1.2 | 2.2 | 2.9 | 5.3 | 8.4 | 10.5 | |

| Rated current | A | 5.9 | 11.3 | 8.2 | 11.7 | 20.0 | 23.4 | |

| Compressor | Type | Rotor type | Flexible scroll type | |||||

| Power | kW | 0.8 | 1.6 | 2.3 | 4.2 | 6.9 | 8.7 | |

| Condenser | Type | High efficiency internal thread copper tube fin type | ||||||

| Fan type | High efficiency low noise axial fan | |||||||

| Evaporator | Type | Water tank coil type | Shell and tube type | |||||

| Water tank capacity | 20 | 40 | 50 | 70 | 100 | 135 | ||

| Water pump | Type | Stainless steel centrifugal pump | ||||||

| Power | kW | 0.25 | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | |

| Pump head | m | 34 | 26 | 25 | 30 | 30 | 27 | |

| Water flow rate | m³/h | 0.46 | 0.89 | 1.6 | 2.6 | 4.0 | 5.1 | |

| L/min | 7.7 | 14.8 | 26.7 | 43.3 | 66.0 | 85.0 | ||

| Refrigerant | Type | HCF/CHFC | ||||||

| Expansion valve type | Electronic expansion valve | |||||||

| Controller | Type | High precision touch screen controller | ||||||

| Pipe connection size | DN | 15 | 20 | 25 | 25 | 25 | 40 | |

| Noise level | dB(A) | 58 | 63 | 63 | 67 | 68 | 69 | |

| Weight | kg | 90 | 120 | 160 | 200 | 280 | 320 | |

| Dimensions | Length | mm | 500 | 600 | 680 | 750 | 1350 | 1510 |

| Width | mm | 500 | 600 | 680 | 750 | 680 | 750 | |

| Height | mm | 950 | 1160 | 1360 | 1480 | 1360 | 1480 | |

Customized specifications are available upon request. Please

- Energy Efficiency

- Innovation

- Safety Features

- Precision Manufacturing

-

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes -

20% Improve heat transfer efficiency by aboutWave-Shaped Fins

20% Improve heat transfer efficiency by aboutWave-Shaped Fins -

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve -

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System -

10% Enhances air circulation by aboutOptimized Airflow Path Design

10% Enhances air circulation by aboutOptimized Airflow Path Design -

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

-

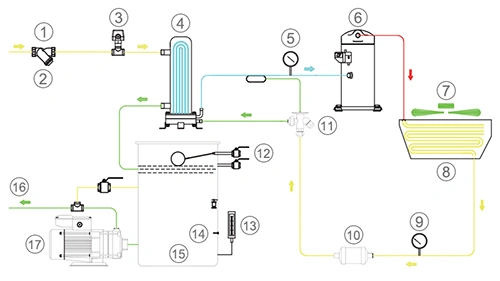

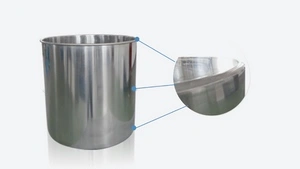

Stainless Steel Evaporator

Stainless Steel Evaporator -

V-Shaped Condenser

V-Shaped Condenser -

Cylindrical Water Tank

Cylindrical Water Tank -

Low-Noise Fan

Low-Noise Fan -

Touch-Screen Controller

Touch-Screen Controller -

Advanced Control System

Advanced Control System

-

Over-Temperature Protection

Over-Temperature Protection -

Current Protection

Current Protection -

Self-Diagnosis

Self-Diagnosis -

Intelligent Antifreeze

Intelligent Antifreeze -

Water Flow Alarm

Water Flow Alarm -

Water Level Alarm

Water Level Alarm -

Pressure Alarm

Pressure Alarm -

Timer On/Off

Timer On/Off

-

Precision Sheet Metal Forming

Precision Sheet Metal Forming -

Stamped Flow Guide Rings

Stamped Flow Guide Rings -

Robotic Bending System (Bystronic, Switzerland)

Robotic Bending System (Bystronic, Switzerland) -

Laser Welding Technology

Laser Welding Technology -

Automated Insulation Material Cutting

Automated Insulation Material Cutting -

Automated Joint Welding

Automated Joint Welding

With over 20 years of experience in the industrial cooling industry, KANSA designs and manufactures a variety of industrial chillers and process temperature control equipment in-house to ensure consistent quality, reliable operation and exceptional temperature stability of ±0.05°C. The company holds CE, ISO9001-2016, ISO45001 and other international certifications, serving more than 70,000 customers worldwide.