9.1-140kW Air-Cooled Industrial Chiller (Split System)

-

Model: ICA-3S~ICA-50S

-

Cooling Capacity: 9.1-140.0kW

-

Temperature precision: ±0.1/±1.0/±1.5°C

-

High Efficiency & Energy Saving

-

Intelligent Control

-

Multiple Safety Features

-

Durable Construction

-

Easy to Operate

-

Simple Maintenance

-

CE Certification

-

Certified Manufacturing Facility

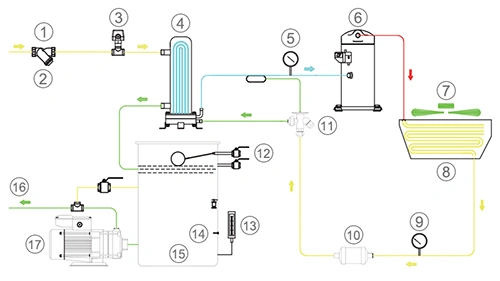

The split-system air-cooled industrial chiller features a design that separates the compressor and condenser (outdoor unit) from the evaporator and water pump (indoor unit). This configuration combines the flexibility of air-cooled systems with the efficiency of water-cooled models, effectively addressing installation challenges in large-scale equipment caused by limited space or heat dissipation constraints.

The chiller is particularly suitable for environments with restricted workshop space, long-distance chilled water delivery, or high indoor heat load requirements such as large laser cutting systems, machine tool cooling, and other industrial applications demanding reliable temperature control and efficient operation.

| Model |

|

|

|

|

|

|

||

| Cooling capacity | kW | 9.1 | 15 | 18 | 23 | 29.5 | 35 | |

| 10³ kcal/h | 7.8 | 12.9 | 15.5 | 19.8 | 25.4 | 30.1 | ||

| Power supply | V/Ph/Hz | 380/3/50 | ||||||

| Total power input | kW | 2.9 | 5.3 | 6.5 | 8.4 | 10.5 | 12.5 | |

| Rated current | A | 8.2 | 11.7 | 12.2 | 20 | 23.4 | 24 | |

| Compressor | Type | Scroll type | ||||||

| Power | kW | 2.3 | 4.2 | 5.1 | 6.9 | 8.7 | 10.1 | |

| Water pump | Power | kW | 0.37 | 0.55 | 0.75 | 0.75 | 0.75 | 1.2 |

| Pump head | m | 24 | 28 | 33 | 30 | 27 | 29 | |

| Water flow rate | m³/h | 1.6 | 2.6 | 3.1 | 4 | 5.1 | 6 | |

| L/min | 26.7 | 43.3 | 51.7 | 66.7 | 85 | 100 | ||

| Water tank capacity | L | 60 | 70 | 70 | 100 | 135 | 135 | |

| Pipe connection size | DN | 25 | 25 | 25 | 25 | 40 | 40 | |

| Noise level | dB(A) | 60 | 61 | 62 | 64 | 65 | 65 | |

| Weight | kg | 120/70 | 140/90 | 160/120 | 180/140 | 210/170 | 230/200 | |

| Dimensions | Length | mm | 680/800 | 750/800 | 750/1055 | 1350/1055 | 1510/1055 | 1510/1400 |

| Width | mm | 680/450 | 750/450 | 750/450 | 680/450 | 750/400 | 750/400 | |

| Height | mm | 1270/765 | 1390/1165 | 1390/1165 | 1270/1165 | 1390/1475 | 1390/1475 | |

| Model |

|

|

|

|

|

|

||

| Cooling capacity | kW | 44 | 58.5 | 69 | 86 | 116 | 140 | |

| 10³ kcal/h | 37.8 | 50.3 | 59.3 | 74.1 | 100 | 120 | ||

| Power supply | V/Ph/Hz | 380/3/50 | ||||||

| Total power input | kW | 15 | 21.1 | 24 | 30 | 41.3 | 48 | |

| Rated current | A | 27.7 | 41.7 | 46.7 | 57 | 76 | 88 | |

| Compressor | Type | Scroll type | ||||||

| Power | kW | 12.5 | 17.4 | 20.2 | 25 | 34.8 | 40.6 | |

| Water pump | Power | kW | 1.2 | 2.2 | 2.2 | 2.2 | 3.5 | 3.5 |

| Pump head | m | 27 | 27 | 26 | 25 | 34 | 29 | |

| Water flow rate | m³/h | 7.6 | 10 | 11.8 | 14.8 | 20 | 24 | |

| L/min | 127 | 167 | 197 | 247 | 333 | 400 | ||

| Water tank capacity | L | 155 | 230 | 230 | 230 | 300 | 300 | |

| Pipe connection size | DN | 40 | 50 | 50 | 50 | 50 | 65 | |

| Noise level | dB(A) | 66 | 67 | 68 | 68 | 69 | 69 | |

| Weight | kg | 260/230 | 380/330 | 420/330 | 460/380 | 750/1450 | 880/580 | |

| Dimensions | Length | mm | 1785/1400 | 2080/1610 | 2080/1610 | 2080/2035 | 2200/2035 | 3000/1610 |

| Width | mm | 915/500 | 1050/1000 | 1050/1000 | 1050/1100 | 1200/1100 | 1200/1000 | |

| Height | mm | 1545/1400 | 1570/1560 | 1570/1560 | 1570/1735 | 1570/1750 | 1570/1735 | |

Customized specifications are available upon request. Please

- Energy Efficiency

- Innovation

- Safety Features

- Precision Manufacturing

-

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes

25% Improve heat exchange efficiency by approximatelyInternally Threaded Copper Tubes -

20% Improve heat transfer efficiency by aboutWave-Shaped Fins

20% Improve heat transfer efficiency by aboutWave-Shaped Fins -

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve

6% Reduces total power consumption by aboutPID-Controlled Electronic Expansion Valve -

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System

20% Improves distribution uniformity by approximatelyOptimized Refrigerant Distribution System -

10% Enhances air circulation by aboutOptimized Airflow Path Design

10% Enhances air circulation by aboutOptimized Airflow Path Design -

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

20% Lowers fan power consumption by approximatelyAutomatic Air Volume Control

-

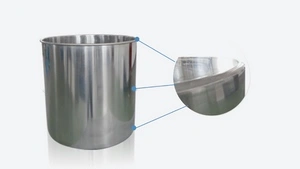

Stainless Steel Evaporator

Stainless Steel Evaporator -

V-Shaped Condenser

V-Shaped Condenser -

Cylindrical Water Tank

Cylindrical Water Tank -

Low-Noise Fan

Low-Noise Fan -

Touch-Screen Controller

Touch-Screen Controller -

Advanced Control System

Advanced Control System

-

Over-Temperature Protection

Over-Temperature Protection -

Current Protection

Current Protection -

Self-Diagnosis

Self-Diagnosis -

Intelligent Antifreeze

Intelligent Antifreeze -

Water Flow Alarm

Water Flow Alarm -

Water Level Alarm

Water Level Alarm -

Pressure Alarm

Pressure Alarm -

Timer On/Off

Timer On/Off

-

Precision Sheet Metal Forming

Precision Sheet Metal Forming -

Stamped Flow Guide Rings

Stamped Flow Guide Rings -

Robotic Bending System (Bystronic, Switzerland)

Robotic Bending System (Bystronic, Switzerland) -

Laser Welding Technology

Laser Welding Technology -

Automated Insulation Material Cutting

Automated Insulation Material Cutting -

Automated Joint Welding

Automated Joint Welding

With over 20 years of experience in the industrial cooling industry, KANSA designs and manufactures a variety of industrial chillers and process temperature control equipment in-house to ensure consistent quality, reliable operation and exceptional temperature stability of ±0.05°C. The company holds CE, ISO9001-2016, ISO45001 and other international certifications, serving more than 70,000 customers worldwide.