A brewery equipment supplier based in Shandong, serving numerous domestic beer manufacturers, faced major temperature control challenges that directly affected product quality, equipment reputation, and market competitiveness.

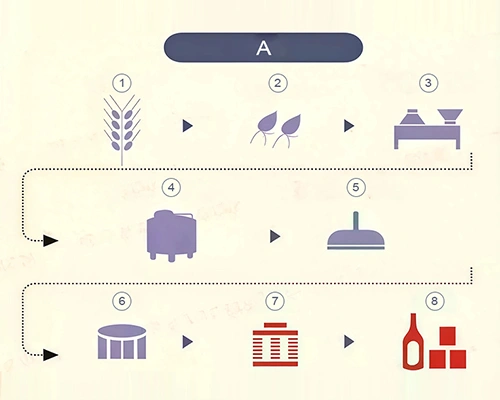

- Barley

- Malted Barley

- Drying & Grinding

- Mashing & Lautering

- Boiling & Wort Cooling

- Fermentation

- Filtration

- Beer Packaging

During the mashing stage, wort cooling was slow, remaining in the 60–80°C for extended periods. This accelerated the formation of dimethyl sulfide (DMS), resulting in unwanted corn-like flavors, oxidation leading to cardboard notes, and significant hop aroma loss. In addition, the delayed cooling cycle prevented timely kettle turnover, reducing overall brewing efficiency.

During fermentation, temperature fluctuations exceeding ±1.5°C disrupted yeast metabolism, causing excessive higher alcohols (harsh taste) and esters (unbalanced aroma). The reduction of diacetyl was also hindered, decreasing foam retention by 20–30%. As a result, flavor consistency varied significantly between batches, undermining product stability.

KANSA provided a customized low-temperature chiller with glycol tank system, featuring the ICA-5M chiller (cooling capacity: 7kW) that continuously supplies −5°C coolant (25% ethanol or 33% glycol solution) for 24-hour operation. The system achieves ±0.1°C precision and offers a wide temperature control range (−35°C to 95°C). It can be fully integrated with the customer’s central control system to meet various brewing process requirements.

The solution effectively resolved temperature control issues across both cooling and fermentation stages, ensuring stable beer flavor and quality while preventing off-flavor formation. Foam retention improved, and production efficiency increased through continuous and energy-efficient operation. The brewery equipment equipped with KANSA chillers received strong market recognition from downstream brewers, establishing KANSA low-temperature chillers as a standard configuration for the client’s brewing systems.